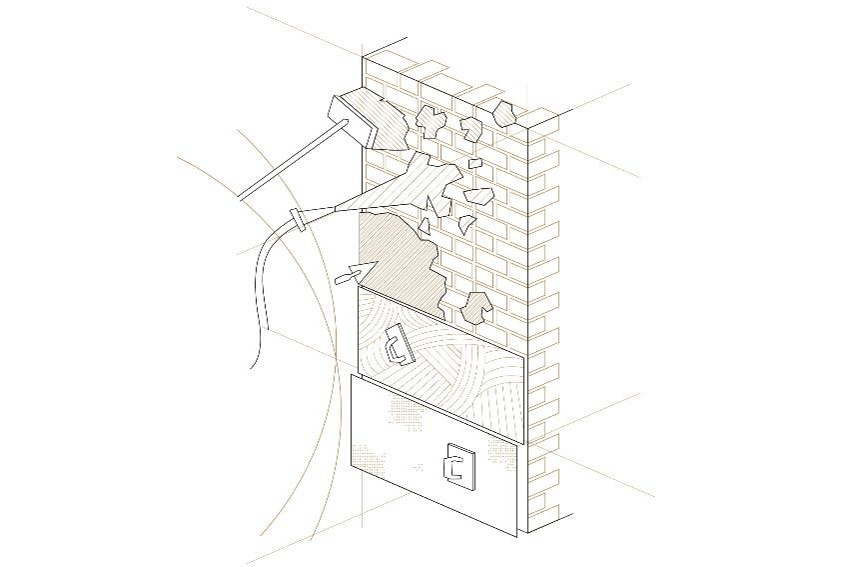

Rising humidity is the phenomenon that occurs at the low point of the wall near the floor and is responsible for the gradual destruction of the coating.

The presence of moisture in the masonry favors the multiplication of microorganisms (fungi). Also, the water that diffuses into the masonry if it freezes in the winter months with the contraction – expansion destroys the existing mortars. Decomposition of mortars can also be caused by salts carried away by the movement of water.

That is why it is very important during the restoration process of a building to use breathable materials, suitable for the treatment of rising moisture, which sanitize the surfaces.

In this tribute we will present you a complete system for combating rising humidity with macroporous coatings that facilitate the perspiration and evaporation of moisture.

In brick or masonry structures where there is a problem of rising humidity, the existing damaged mortars are first thoroughly cleaned and after leaving the appropriate time for the release of moisture, a coating system based on hydraulic lime is applied.

This workflow involves applying a first coat of substrate followed by a base coat of sulfate-resistant coating combining good mechanical strength and high perspiration, and finally a finishing coat.

The finishing layer can be reinforced with an alkali-resistant mesh minimizing the formation of cracks. It is worth mentioning that the specific product line of EX NOVO is particularly suitable for application in historic buildings.

The products of the system are:

SUBSTRATE

BASE COAT

FINAL COAT

or

FASSANET 160

DETAIL:

The first coat of coating – substrate RINZAFFO 720, acts as an adhesion bridge with the base coat.

After at least one day, apply the base coat of INTONACO MACROPOROSO 717.

Both of these products are resistant to sulfates and remove moisture. They prevent the entry of rainwater and guarantee high breathability with the external environment.

As a final layer – finish we apply either FINITURA 750 or FINITURA IDROFUGATA 756. These 2 coatings offer a variety of colors and contribute to maximum water repellency. Combined, they can also be reinforced with an alkali-resistant mesh such as FASSANET 160.

In order to have a complete solution against the rising humidity, all the mortars of the system must be applied, in the order described.

The above products are produced by the Italian House Fassa Bortolo, whose company, Dalkafoukis Oikos is the official distribution company in Greece.